Insertion Devices

R&D of superconducting insertion devices

|

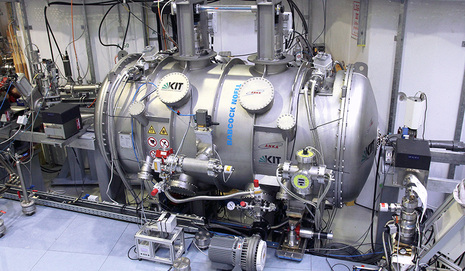

The Insertion Devices (ID) group develops insertion devices for accelerator and synchrotron facilities. The group pioneered the development of superconductive undulators and was the first worldwide to test them with beam. In 2018, the group installed the first commercially available superconducting undulator SCU20 in the storage ring KARA at KIT. SCU20 produces brilliant X-ray light without failure since its installation. For details see KIT press release. The activities include development of superconducting planar IDs, instruments and tools for quality assessment of the magnetic field of superconducting undulators, and integration of new superconducting IDs in the storage ring KARA and KIT synchrotron. For understanding the beam heat load mechanisms in a cold bore, the group led a large collaboration and developed COLDDIAG, a cold vacuum chamber for diagnostics. Within KIT collaborations applications of new superconducting materials to insertion devices are investigated. In addition, projects such as COLDIDAG are performed in collaboration with European partners (CERN, Diamond Light Source, Frascati National Laboratory, Rome University “La Sapienza,” STFC Daresbury Laboratory, STFC Rutherford Appleton Laboratory, University of Manchester, Cockcroft Institute of Science and Technology, and Lund University MAX-Lab) and industrial partners such as Bilfinger Noell GmbH. |

|

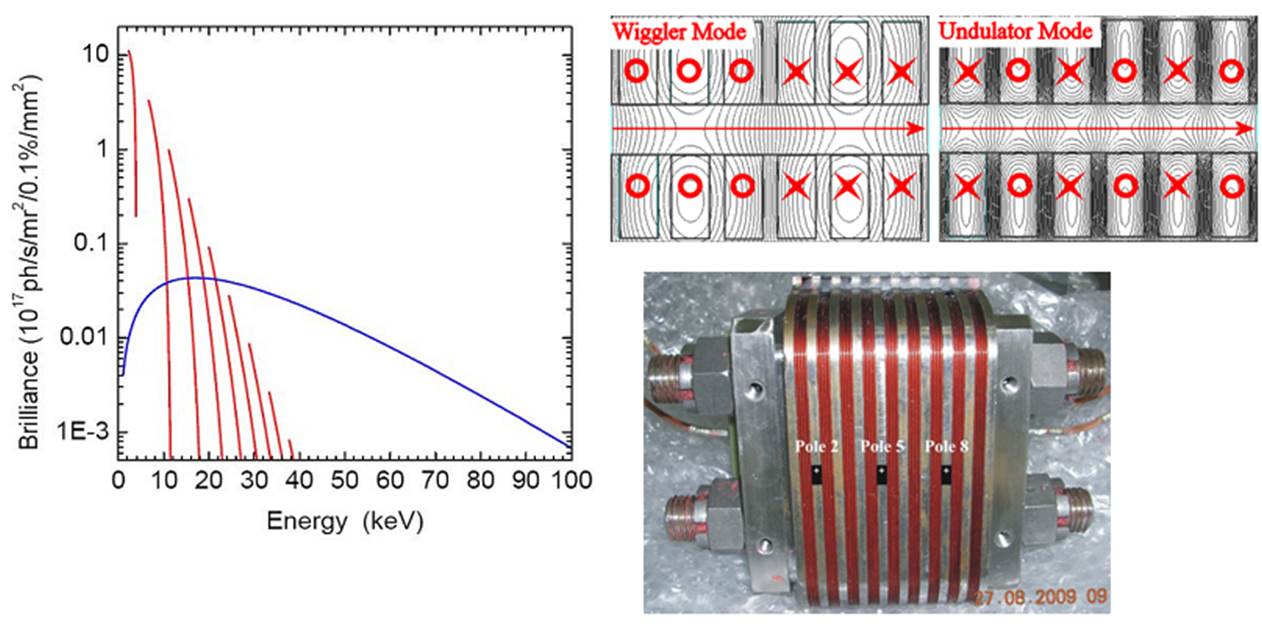

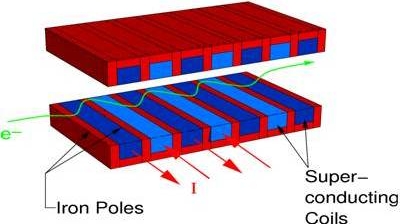

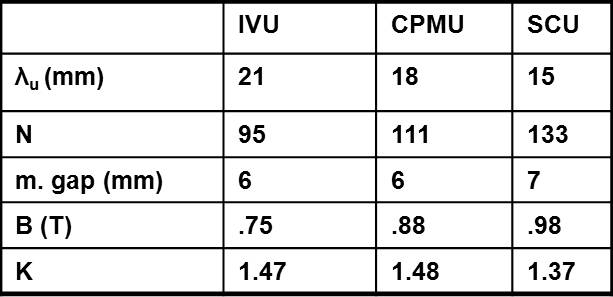

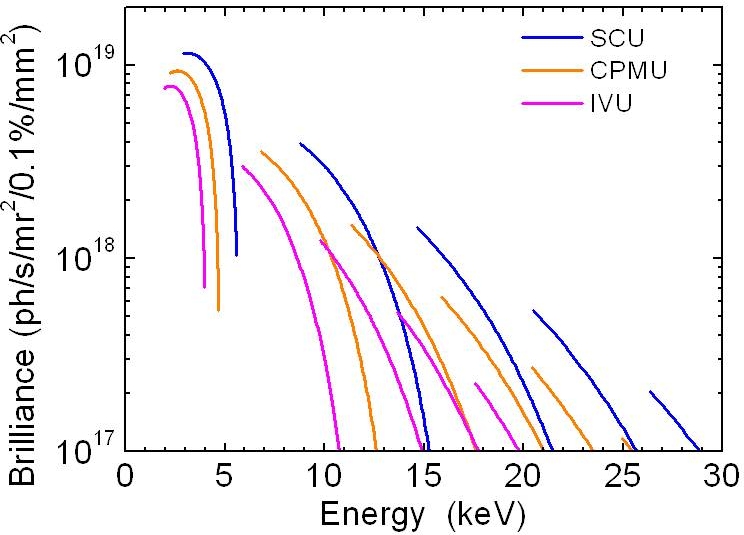

Light sources make use of insertion devices (ID) to produce synchrotron radiation of highest brilliance. In 2004, Hara et al. described the concept of cryogenic permanent magnet undulators (CPMU) as an evolution of in-vacuum undulators (IVU). Superconducting undulators (SCU) can reach, however, for the same gap and period length, higher fields even with respect to CPMU devices, allowing to increase spectral range and brilliance. |

|

Performance comparison of a SCU, a CPMU and an IVU considering the same magnetic length and the same vacuum gap. A given photon energy is reached by a SCU at a lower order harmonic: 20 keV can be reached with a SCU at the 5th harmonic, CPMU at the 7th harmonic, and IVU at the 9th harmonic. With a SCU it is possible to relax the beam properties and/or the magnetic field quality. |

Undulators and test stands

SCU15 - SCUW - CASPER I - CASPER II - COLDDIAG - New Materials

| SCU15 | |

| A 1.5 m long superconducting undulator with a period length of 15 mm has been successfully developed, installed, and tested in collaboration with the company Bilfinger Noell GmbH Thanks to high-precision components, SCU15 fulfills stringent demands on the accuracy of the magnetic field. This makes SCU15 the first full-length superconducting device to reach higher peak magnetic fields than comparable cryogenic permanent magnet undulators. |

|